38 best way to label warehouse racking

What are the best way to label warehouse racks? - Creative Safety Supply The best ways to label warehouse racking lies in the clarity of the location label. Location labels are what mark the place of an item that can be found by scanning a barcode, which then will give the scanner the precise location of the product to go find in the warehouse. Creating an Efficient System Rack Beam Label Cover Up Tape - Label Magic™ | Dasko Give your racks an instant face lift with Label Magic™! This label cover up tape allows you to easily re-face your rack beams by applying it directly over old warehouse labels and markings. The solution eliminates previous signage clutter and the result is clean rack beams that look just like new. Features & Uses

Warehouse Racks Labeling Guide & Idea - SPS Ideal Solutions Get the Right Label as per the Application: Get the label considering the surfaces in which they are applied to. If the demand is for a warehouse rack label that can be easily removed and replaced to other surface, then go for choosing a magnetic label.

Best way to label warehouse racking

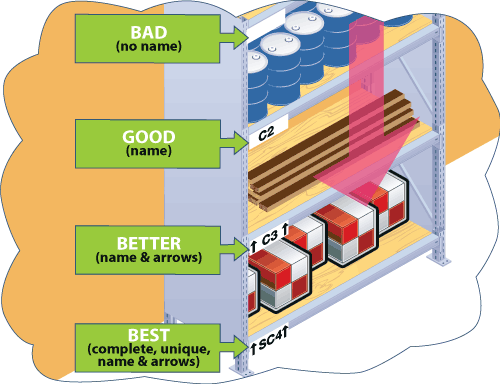

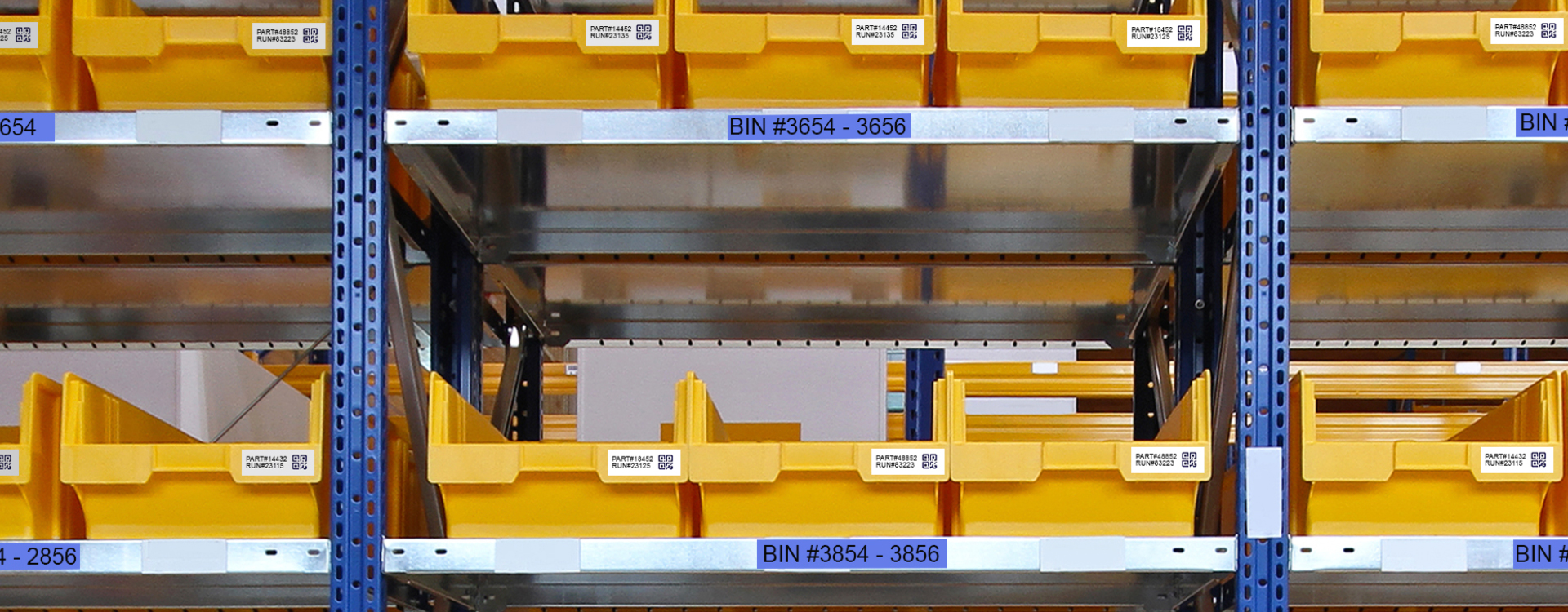

3-Step Guide to Choosing the Right Warehouse Labels - Camcode If you need to label bulk storage, such as containers and totes, pallets, or even the floor or ceiling, there are a multitude of warehouse label options for a complete warehouse label solution: Container Labels - Label your totes and containers with Metalphoto® Aluminum Warehouse Tote Labels or Premium Polyester Plus Tray Labels. What Are The Ways to Label Bin and Rack Locations? | SOLUM It woud be best to map and segment your warehouse and assign specific location names for each of these segments Establish a Bin and Rack Numbering and Labeling Scheme Each aisle, rack, shelf or position should have a specific location code and should be properly labeled based on this location code. Warehouse Rack Labeling Ideas: Keep An Organized Warehouse Use a durable and easily visible material for the labels. The label should be placed in a location that is easy to spot from a distance. Use symbols or colors to indicate different types of items or areas within the warehouse. By following these tips, you can ensure that your warehouse is well-labeled and organized.

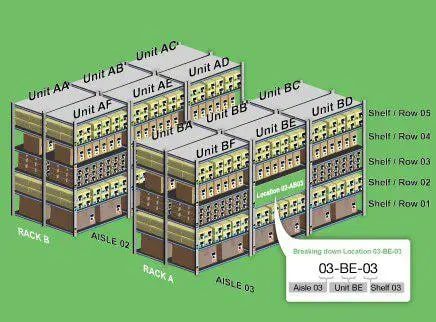

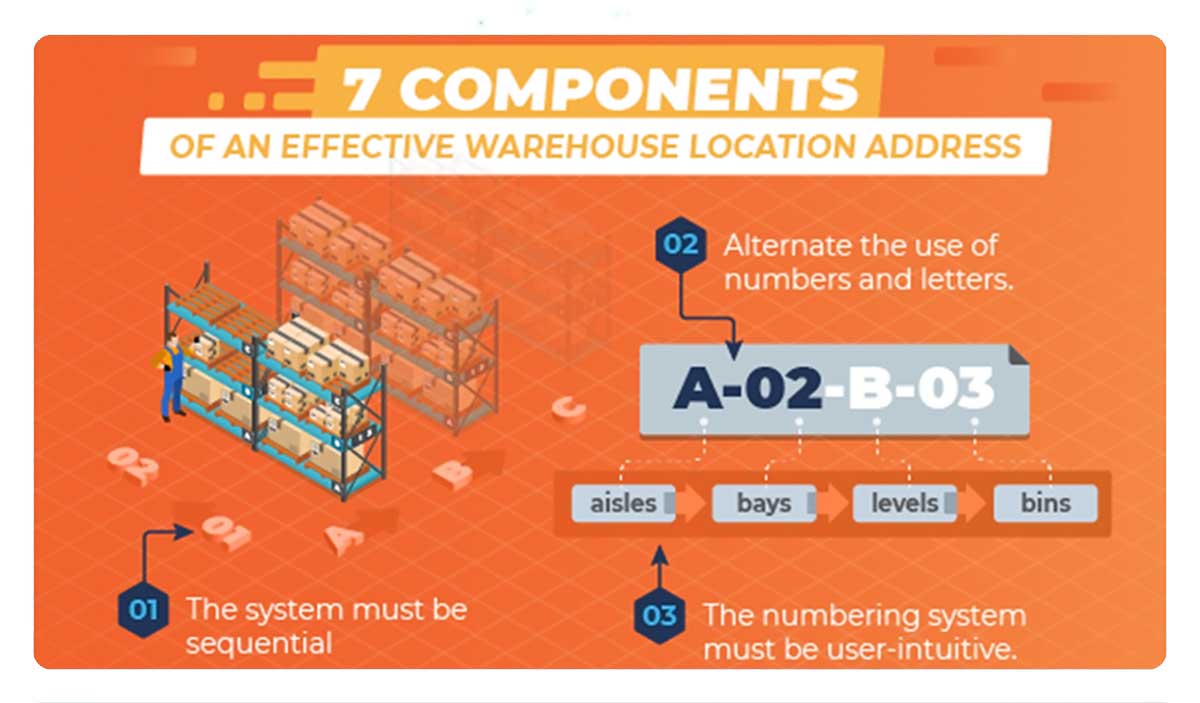

Best way to label warehouse racking. How to Label a Warehouse - Express Corp As with most rack labels, multi-level racks are a type of rack labels, that can easily be color coded for identification, and they can also be placed on aisles for easy accessibility. Shelves: The common and preferred method of warehouse shelf labeling is by section. Warehouse Labeling Ideas: Warehouse Rack Labels and Labeling - BlueCart The best warehouse label maker in 2022 is DYMO. It's considered to be the best warehouse label maker for all-around use thanks to its high-quality label printing software. DYMO is compatible with macOS and Windows which means that it's easy to print all kinds of labels. New Warehouse Design? Tips on How to Label Warehouse Racking - LIDD Combining the aisle, rack and/or position and level gives you your final numbering format. From here you can play with hyphens to create the most legible format for your warehouse. We encourage you to play around with your numbering system to find out what works best in your warehouse design. How To Optimize Warehouse Efficiency With Right Labeling Methods The best way to create an address system and begin labeling focuses on optimal pick paths. Your layout and labels need to create a direct line from point A to point B with workers taking the shortest routes possible. With the right labeling method, you'll see efficiency. Without it, get ready for the chaos.

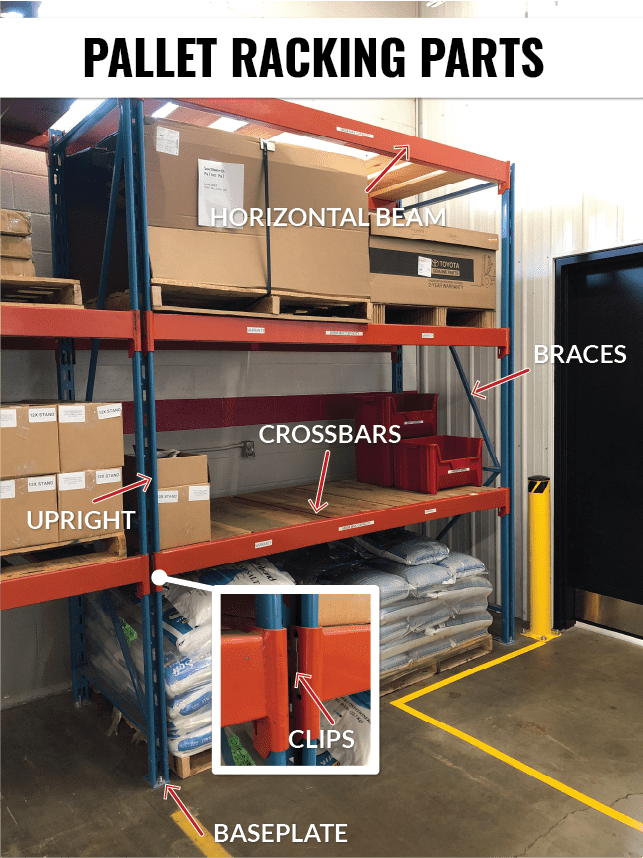

Warehouse Locations and Bin Labeling: Best Practices and Tips - SkuVault Typically, it is the most specific a warehouse location can get. The next level of location naming is by shelf (AKA row). This is categorized as the horizontal space spanning across a rack. Racks (AKA units or section) can be thought of as large sections of shelving units that store your product. 5 Keys to Warehouse Rack Labeling | Express Instead, there are different methods used to: 1) Identify racks - As an example, consider the many ways that sections or units of shelving can be positioned to hold gear. There might be a single, elongated unit or many smaller, single units. How to label shelves in your warehouse for improved efficiency The three steps to labelling warehouse racking for improved efficiency are: Define your warehouse racking identification method Label warehouse racking from bottom to top Identify the best warehouse racking labels Clearly identify your warehouse racking or shelves 4 Proven Options for Relabeling Warehouse Racks - ID Label Inc. Magnetic warehouse rack labels are popular because they are easy to place and move, and they offer a good long-term return on investment. 3. Removable Warehouse Labels If your beams are in good shape, consider using a preprinted, removable barcode label. Like the other options above, a removable label makes it easy to relabel rack locations.

Creating an Effective Warehouse Storage Numbering System with Barcodes ... The best way to begin your process of warehouse location mapping is to walk through the warehouse and conduct an assessment that identifies the most ideal picking strategy. Take note of streamlined routes, highly trafficked areas, and other spots that may lead to trouble or waste. Generate Custom Barcode & Warehouse Labels - Avery From Surface Safe ID labels that allow you to quickly and easily update warehouse rack labels to durable inspection labels and self-laminating labels, create custom warehouse labels you can rely on. Easily create barcodes for your warehouse rack labeling system, inventory management, asset tracking and more with the data-merge feature on our ... Supply Chain & Logistics Basics: Best Practices for Labeling the Warehouse Do not treat warehouse and inventory labeling as an afterthought as it often has more impact on your business than you may realize. To learn more about supply chain best practices like these contact Datex experts today at marketing@datexcorp.com or 800.933.2839 ext 243. How to Label a Warehouse Rack - Camcode At Camcode, we provide rack labels for all applications, environments, and price points. For a more durable alternative to paper-based labels, Polyester Warehouse Rack Labels are a great choice. These specialized labels serve as highly-durable, permanent labeling solutions that adhere to a variety of surfaces - including uneven or bumpy surfaces.

Warehouse Rack Labeling Ideas: Keep An Organized Warehouse Use a durable and easily visible material for the labels. The label should be placed in a location that is easy to spot from a distance. Use symbols or colors to indicate different types of items or areas within the warehouse. By following these tips, you can ensure that your warehouse is well-labeled and organized.

What Are The Ways to Label Bin and Rack Locations? | SOLUM It woud be best to map and segment your warehouse and assign specific location names for each of these segments Establish a Bin and Rack Numbering and Labeling Scheme Each aisle, rack, shelf or position should have a specific location code and should be properly labeled based on this location code.

3-Step Guide to Choosing the Right Warehouse Labels - Camcode If you need to label bulk storage, such as containers and totes, pallets, or even the floor or ceiling, there are a multitude of warehouse label options for a complete warehouse label solution: Container Labels - Label your totes and containers with Metalphoto® Aluminum Warehouse Tote Labels or Premium Polyester Plus Tray Labels.

Post a Comment for "38 best way to label warehouse racking"